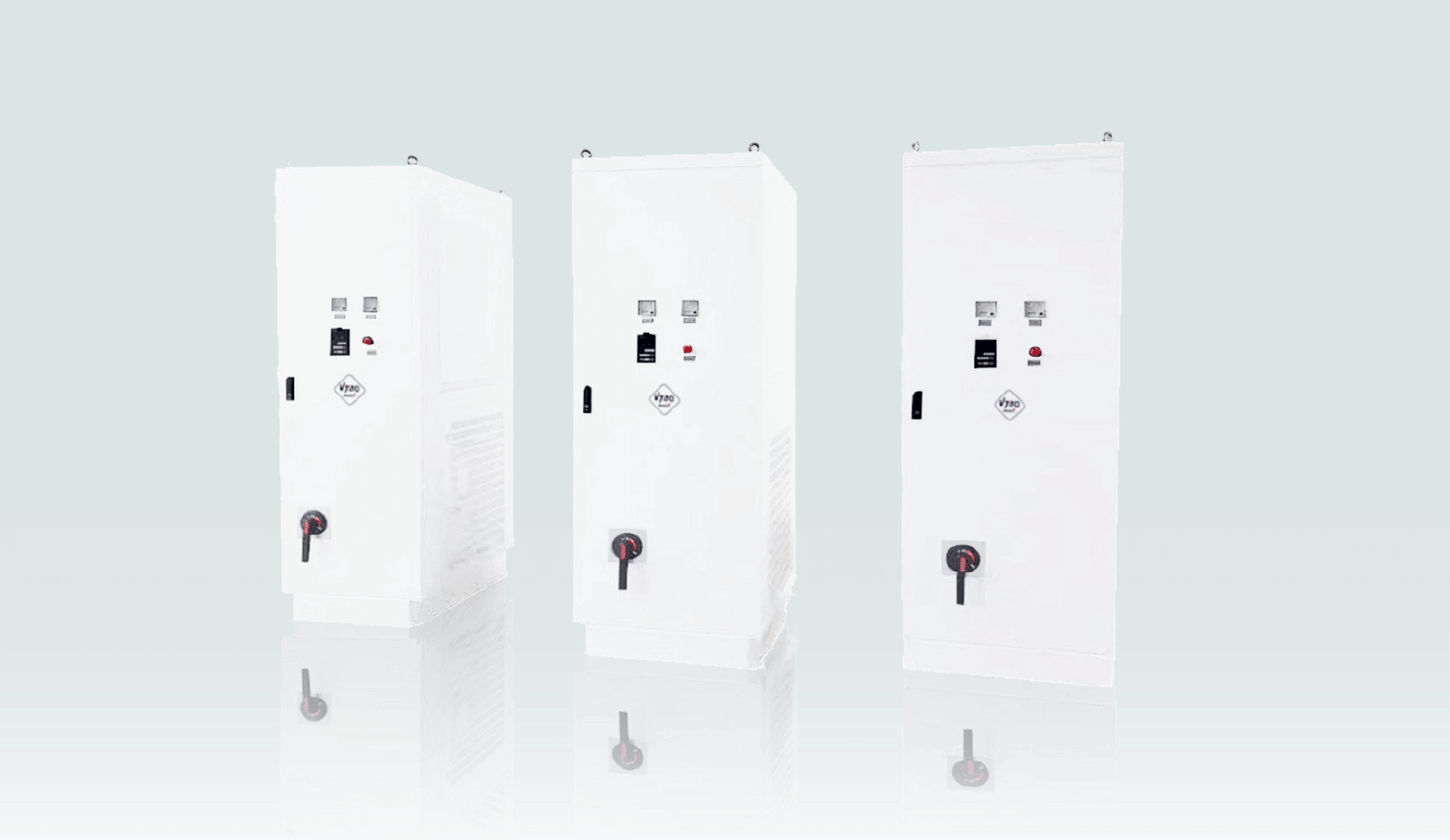

In addition to electric motors and gearboxes, VYBO Electric is also involved in various types frequency converters. The most common reason for choosing a frequency converter is the possibility of more efficient use of the electric motor, for example when steering is needed for asynchronous motors. In the following article, we’ve prepared some tips to help you get started operation and maintenance of the frequency converter.

The basic requirements for frequency inverters certainly include not only reliability, but also friendly and easy to use. To be fully satisfied with the variable frequency drive suppliers at selection and subsequent operation of the frequency converter is worth proceeding with adequate care. VYBO Electric knows that it may not always be easy and that’s why you a team of experts will help you not only to select the right frequency converter, but also to you will also help during operation and maintenance.

How to avoid problems with frequency inverters

It is worth mentioning at the outset that modern frequency inverters are designed as maintenance-free devices. After proper installation and commissioning, they do not usually require a special one care. However, it is certainly appropriate, at least from time to time, to the frequency converter pay attention. How to? First of all, always follow the vfd manufacturers instructions when operating the frequency converter.

The frequency converter you are using should match not only your requirements but also the characteristics the electric motor or the conditions in which it is operated – for example, a dusty environment or high humidity environment. One of the most sensitive parts of the frequency converter is cooling therefore, sufficient air circulation around the inverter and regular inspection should not be forgotten cooler and fan functionality.

What to do if something goes wrong? Frequency converters are already equipped with a very sophisticated design diagnostics to quickly find out what the problem is. Errors occur most often due to overload, respectively. misuse. Therefore, do not hesitate to ask any questions to contact our team.

More information not only from the world of frequency inverters can be found at https://vyboelectric.eu.